Contact us today to learn more about humidity for the Composite Manufacturing Industry...

Why Humidify... For the Composite Manufacturing Industry

Composite applications such as creating carbon fiber or similar materials require absolute humidity control to guarantee manufacturing processes that enable for consistent quality and durability.

Overview

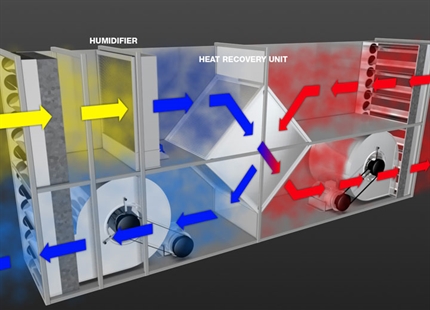

Composite applications such as creating carbon fiber or similar materials require absolute humidity control to guarantee manufacturing processes that enable for consistent quality and durability. Achieving balanced relative humidity (RH) and maintaining it at regulated levels plays a key role in protecting from overly dry or moist air, protecting materials, final products and production flow from being negatively impacted in a multitude of ways.

More Efficient Quality Control

Maintaining relative humidity levels of between 40% and 60% ensures that the integrity of composite products isn’t threatened by dry or excessively moist conditions, which would otherwise cause damage in the form of cracks or inconsistent coatings formed during the curing process. Optimal composite quality control ensures for the highest percentage of market-ready products, maximizing profit potentialities. In short, proper humidity makes it easier to meet specified quality control standards.

Effective Drying/Curing Times

The tensile strength and modulus of composite materials are highly dependent on the curing process. The temperature and humidity level of composite-focused environments must be maintained to ensure both properties set at the designed values and maximize the durability and the adhesive efficiency of coated materials. Proper humidity control enables for highly efficient and effective drying and curing times for composite products.

Efficient Production and Minimal Wastage

The resin found within composites is highly sensitive to temperature and moisture fluctuations of any variety. If the application environment is not maintained, the structure of a composite can have up to a 30% reduction in both modulus and ultimate strength for the matrix. With proper humidification, material and product wastage can be minimized and manufacturing production rates can be improved to be more efficient.

Benefits of humidification in composites include:

- Reduce material and product waste.

- Improve production output.

- Assists to easily adhere to quality control standards.

- Highly efficient drying and curing times.

Why Humidify... For Abattoir

In-duct evaporative cooling strategies

Packaging humidification

Why Humidify... Cleanrooms & Laboratories Humidification

Why Humidify... For Retail Spaces

Why Humidify... For Bakeries

Why Humidify... For Offshore Oil & Gas Platforms

Why Humidify?... 5 Important Points for HR Managers to Consider

Why Humidify... For Hospitals and Care Facilities