-

LM Wind Power

-

Siemens

-

Vestas

-

GE

Contact us today to learn more about humidity for Wind Energy...

Why Humidify... For Wind Energy

The wind energy manufacturing process requires effective humidity control to operate efficiently. Insufficient humidity can impair coating applications and curing rates, resulting in damaged components, waste and decreased production output. Improve production output, elevate product quality and boost ROI with improved humidification control in your wind turbine and / or blade component manufacturing facility.

Ensure Manufacturing Efficiency and Product Consistency with Humidity Control

Ensuring an ideal environment through the manufacturing process is integral to product quality and output efficiency. When the manufacturing environment is not controlled, it often causes dimensional changes in the products which impede their function. Insufficient humidity levels can lead to brittle components and shrunken or warped parts, which can cause a host of problems due to the tight tolerances when the components shape or size no longer fits proper dimensions for planning, shaping or assembly.

Improve Dust Suppression During Sanding Process

Static electricity problems in a blade (composite) manufacturing environment occur when dry air causes surfaces to become charged with static electricity. This contributes to a variety of problems including dust fires and static explosions. In some cases, static electricity can also affect the way paints and finishes adhere to composite materials.

Inadequate humidity escalates the development of dust and the intensity of dust swirl in indoor spaces. Maintaining an adequate humidity level throughout your production facility ensures that the dust in the air is enclosed in a film of water. The dust particles absorb the humidity in the air and fall to the

ground, where they can be removed with ease during normal cleaning processes.

Suppress dust during sanding operations by maintaining a consistent humidity level of 40-60% RH throughout your facility. A correct humidification level lowers the risk of dust explosions for dust from combustible materials. Adequate humidity cleans the air of dust faster, reducing the risk of fine dusts in the air, which can cause potential problems to your employees if inhaled and can undermine the production of your products. Proper air humidification also offers odor neutralisation, an important added benefit of air humidification in waste processing, but also for many chemical manufacturing processes.

Consistent Quality During Paint Application

Paint and coating applications require specific environmental standards, with strict temperature and RH requirements. Proper humidity is required for effective dust suppression and effective adhesion for coatings requiring a controlled electrostatic charge.

By ensuring an ideal environment of 70% RH throughout your facility, you will be able to better maintain consistent quality during paint and coating application. These conditions are key for proper electrostatic paint and powder coating application and paint booth environment control. Without proper control, coating adhesion and durability are compromised, undercutting your product.

Eliminating Static in Electronics Assembly

Electrostatic discharge (ESD) occurs with the sudden flow of electricity between two electrically charged objects coming into contact with one another. When objects holding different charges come into contact, or when the dielectric between them breaks down, a visible spark can be triggered, which can damage electronics and pose safety concerns for facility operations.

Maintaining a consistent humidity level between 40-50% RH lowers surface resistance on manufacturing equipment and

products, as well as on communal areas including floors, carpets, table mats and other susceptible areas. When humidity levels drop below 40% RH, this protection disappears and routine employee activities lead to objects being charged with static electricity, posing a safety risk of serious shock for employees and increasing the possibility of damage to or defects within electronic components and devices.

Improve Energy Efficiency and Cost Savings through Adiabatic Cooling

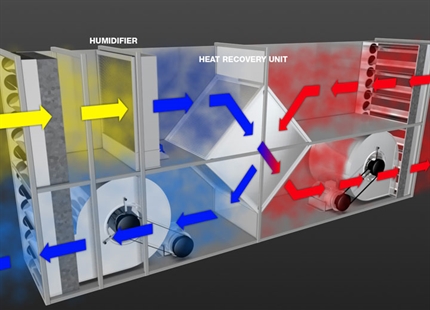

Evaporative or adiabatic cooling is a process that introduces liquid water directly into the air without the need for adding thermal energy (heat) to the water. As the water evaporates, it draws heat from the air to drive the phase change from liquid to vapor. Evaporative or adiabatic humidification systems installed directly in a ventilation airstream result in both increased humidity and cooling of the air. Reducing mechanical cooling requirements offers significant energy savings for manufacturing facilities.

Adiabatic humidification solutions allow a facility to experience reliable and consistent humidity levels and air quality conditions, while also providing an opportunity to greatly reduce energy use required for cooling. Implementing an evaporative cooling humidification solution allows a facility to run at optimum efficiency, reducing energy use and operation costs.

Benefits of humidification for the wind energy industry include:

- Increase production output and productivity

- Boost ROI of facility production and operations

- Maintain and improve product quality

- Improve facility and operations safety

- Decrease waste from damaged components

Why Humidify?... 5 Important Points for HR Managers to Consider

Why Humidify for... Life Sciences

Why Humidify... For Convention Centers

In-duct evaporative cooling strategies

Home humidification

Humidification for Eyes and Skin

Why Humidify... For Cheese Curing

Packaging humidification

Why Humidify... For Egg Incubators