Contact us today to learn more about humidity for the printing industry...

Why Humidify... the Printing Industry

In the increasingly competitive print market where return on investment really matters, humidity control is essential to maintain quality and productivity at all stages of production.

Paper and ink

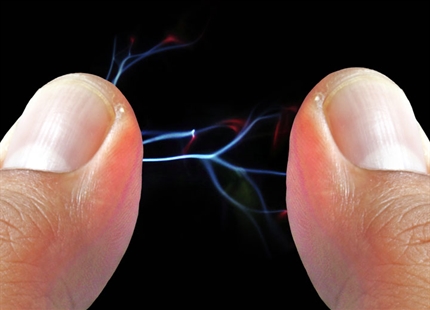

Paper is very hygroscopic, which means it loses moisture rapidly when exposed to dry air. Sheet and web roll paper is typically produced and wrapped to stay in equilibrium with air with a relative humidity of 50±5%RH. When the ambient humidity falls below this level, paper loses water to the environment from exposed surfaces, changing its shape, dimensions and physical properties. Below 40%RH, the movement of paper on paper and other surfaces generates electrostatic charges, attracting dust and making it difficult to handle. The problems are most pronounced in hot summers and cold winters, when the relative humidity can fall below 20%RH even in temperate climates.

Where water-based inks are used, a higher relative humidity of 55±5%RH is typically recommended, and some ink manufacturers recommend 60%.

Platemaking

When the protective film or paper is removed from plates, electrostatic charge is generated if the relative humidity drops below a threshold of 40%RH. This attracts dust and grit to an otherwise unblemished surface, makes handling difficult and also generates sparks. Maintaining an environment of 45%RH prevents this.

Digital printing

The paper problems experienced elsewhere in printing apply equally to digital printing but electrostatic problems associated with machinery can be a particular issue. To counter this, a relative of 50-55%RH is recommended.

Sheet fed offset

A dry press hall means the edges of unwrapped paper lose moisture rapidly. Tight edges result, making the paper curl, which causes misfeed, with misregister, dot doubling and creasing as the paper passes between blanket and impression cylinders.

Misfeed also occurs due to electrostatic build up, which also causes stacking difficulties coming out of the press. Printed work awaiting another pass continues to change, with misregister being a particular problem.

In dry air, work passing to finishing suffers from paper sticking and creasing due to electrostatic, and paper cracks on folds. The impacts of dry air can be so severe that printing stops altogether. Maintaining a relative humidity of 50-55%RH in the press hall and bindery resolves these issues

Web printing

If air is too dry in the paper store, laydown area and reel stand, the exposed edges of the paper rolls loose moisture and shrink. On the web press, the paper is under greater tension at its edges than the centre, which causes the edges to tear, leading to web breaks. The result is substantial downtime as the paper is spliced or rethreaded through the press.

In a dry press hall, the rapid passage of paper through the press generates electrostatic charge, which becomes a particular problem as the printed work passes to finishing for cutting, trimming and folding, due to sticking paper.

Web printing is highly productive and any loss of production is costly, but problems relating to dry air can be addressed by maintaining the relative humidity at 50-55%RH. In flexo, with water-based inks, 55-60% is required.

Benefits of working with Condair on your print humidification project:

- Extensive expertise in all printing processes from projects around the world.

- Comprehensive product range to precisely meet a printer's requirements.

- Full service of expert advice, design, supply, installation, commissioning, maintenance and spare parts.

- Ability to provide innovative, proven solutions.

- Low energy systems to reduce operating costs and improve humidity control.

- Low maintenance solutions that minimize on-going service requirements.

- Increased productivity, decreased waste, improved product quality resulting in higher profits.

Humidification for the Printing Industry

In the increasingly competitive print market where return on investment really matters, humidity control is essential to maintain quality and productivity at all stages of production.

Print and Paper FAQ's

-

Dry air will cause increased static, which will result in paper sheets sticking and machine feed issues. Incorrect print room humidity can also cause dimensional changes to the paper itself, as it either loses or gains water from the air. This can cause paper curl and registration issues.

-

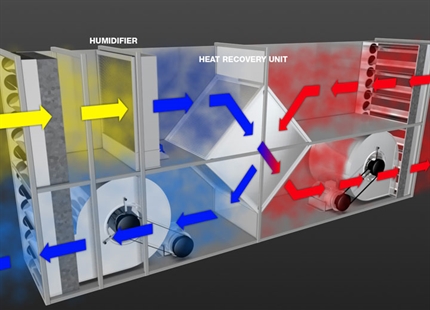

Maintaining optimum print room humidity levels year-round will require a commercial humidification system. Other steps that can be taken include minimising the time paper is exposed to the air prior to printing and acclimatising paper prior to unwrapping if it has been stored at a different temperature than the print room.

-

Most printing processes and paper storage areas would benefit from maintaining a relative humidity of 45-55%RH.

-

A simple hygrometer will tell you what your humidity level is. If you are experiencing static or annoying sparks, then this is a good indication that your humidity level is too low.

Why Humidify... For Abattoir

In-duct evaporative cooling strategies

Are you an Engineer working on a project that needs humidification?

Why Humidify... For Retail Spaces

Why Humidify... For Cheese Curing

Eliminating static with humidification

Why Humidify... For Concert Halls