This guide explains how maintaining proper humidity levels in your facility will improve production output, elevate product quality and ultimately, boost ROI.

Contact us today to learn more about humidity for Food Processing...

Why Humidify... For Food Processing

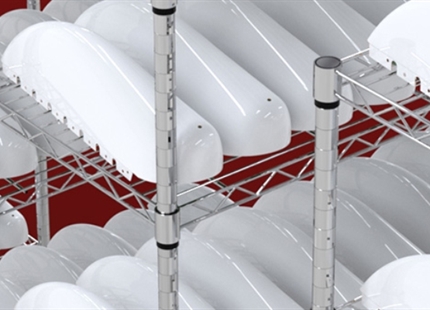

During production, processing, packaging and storage of food, compliance with hygiene and handling regulations is of decisive importance for a high product quality. At the same time, to ensure trouble-free efficient production processes, constant, closely monitored room temperatures and room humidity must often be ensured in addition to good indoor air quality.

These are, however, continuously impaired by moisture ingress due to warm, humid outside air, as well as by the moisture released by personnel and products. Depending on the type of food and its processing, there is a wide range of conditions to consider from high room temperature with high humidity to low room temperature with low humidity. This is especially of concern where hygroscopic substances such as powders, flour and sugar are used and processed. Low humidity is of utmost importance to avoid product clumping and production downtimes.

Once products like cookies, potato chips, and pretzels are produced, the humidity level for storage is as equally important to maintain their freshness and crispness. Or in the case of bread and pastries the effective use of dehumidification systems serves to prevent mold formation and aids in maintaining product quality.

Low humidity levels are also important when labelling bottled beverages as excessive humidity in the vicinity of production can damage the label and also cause it to loose adhesion.

For this purpose, various processes and techniques for particularly reliable, efficient and economical air dehumidification are presented. The dehumidifiers to be used for this purpose can, depending on their functional principle and performance, separate even very large quantities of water vapor from the air in a very short time and thus ensuring all required moisture levels from medium to very low.

Why Humidify... For Clean Rooms

Why Humidify... For Egg Incubators

Humidification for Eyes and Skin

Why Humidify... For Supermarkets

Spa & Wellness

Humidification for Instruments

Why Humidify... For Mushroom Growing

Why Humidify... For Allergies

Why Humidify... For Composites