This four-page guide explains how maintaining proper humidity levels in your facility will improve production output, elevate product quality and ultimately, boost ROI.

Humidity Control for the Electronics Industry

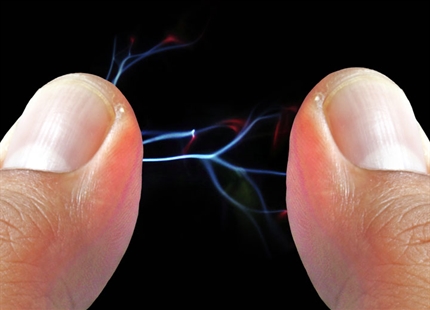

Eliminate harmful electrostatic discharge with proper humidification

Electronic devices, printed circuit boards, components and data are highly sensitive to electrostatic discharge. Correct humidity levels are essential to minimizing the damage caused by ESD.

What is ESD?

Electrostatic discharge (ESD) is the sudden flow of electricity between two electrically charged objects caused by contact. The ESD occurs when differently-charged objects are brought close together or when the dielectric between them breaks down, sometimes creating a visible spark. However, many ESD events occur without a visible or audible spark. A person carrying a relatively small electric charge may not feel a discharge that is sufficient to damage sensitive electronic components. These invisible forms of ESD can cause outright device failures, or may affect the long term reliability and performance of electronic devices. The effects of ESD on some electronics may not become evident until well into their product life.

Static Electricity

One of the causes of ESD events is static electricity. Static electricity is often generated through tribocharging – the separation of electric charges that occurs when two materials are brought into contact and then separated.

Examples of tribocharging include walking on a rug, rubbing a plastic comb against dry hair or rubbing a balloon against a sweater. The friction between two materials results in tribocharging, thus creating a difference of electrical potential that can lead to ESD.

Another cause of ESD damage is through electrostatic induction. This occurs when an electrically charged object is placed near a conductive object isolated from ground. The presence of the charged object creates an electrostatic field that causes electrical charges on the surface of the other object to redistribute.

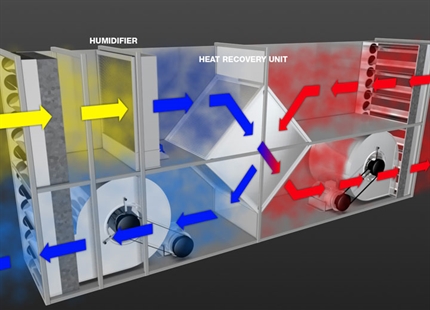

Humidity Control – The Ideal Solution to Eliminate ESD.

With a humidity level of 40% RH, surface resistance is lowered on floors, carpets, table mats and other areas.

Humidifiers add moisture to the air, and the moisture in the air forms a thin protective “film” on surfaces that serves as a natural conductor to dissipate electric charges. When humidity drops below 40% RH, this protection disappears and normal employee activities lead to objects being charged with static electricity.

Benefits of humidification for electronic manufacturing include:

- Increase production output and productivity

Humidity control minimizes the buildup and discharge of static electricity, reducing the risk of ESD-related failures during manufacturing processes.

- Boost ROI of facility production and operations

- Maintain and improve product quality

- Improve on-time deliveries

Manufacturing process stability: Humidity control helps stabilize the manufacturing environment, ensuring consistent and predictable process conditions.

- Improve indoor air quality for employee health

Electronics FAQ'S

Electronics FAQ'S

-

Humidity control helps to eliminate electrostatic discharge by adding moisture to the air, which forms a thing protective film on surfaces that serves as a natural conductor to dissipate electric charges.

-

Statis electricity is a concern in electronic manufacturing because it is one of the causes of ESD events, which can damage electronic components and affect the reliability and performance of electronic devices.

-

The ideal humidity level for preventing ESD in electronic manufacturing is 40% RH. At this humidity level, surface resistance is lowered on floors, carpets, table mats, and other areas, which helps to dissipate electric charges and prevent ESD events.

Watch this short video

to learn more about the benefits of humidity control for electronics.

Why Humidify... For Yoga Studios

Paper & pulp production humidification

Why Humidify... For Printing

Why Humidify... For Offshore Oil & Gas Platforms

Eliminating static with humidification

Why Humidify... For Supermarkets

Packaging humidification

In-duct evaporative cooling strategies

Why Humidify... For Mushroom Growing