Contact us today to learn more about humidity for the Textile industry...

Why Humidify... the Textile Industry

Every textile product is affected by the relative humidity of the environment in which it is produced particularly natural fibers. Low air humidity can dry a fiber causing its internal moisture content to fall. If this moisture content drops below the optimum level during processing, a manufacturer can experience a drop in productivity for a number of reasons.

As fibers dry their tensile strength is impaired, they become less flexible, thinner and more brittle. If a fiber or thread breaks while being processed, textile machinery needs to be manually re-threaded, leading to downtime and reduced efficiency.

Product weight - preventing moisture loss during a textile’s processing and storage can reduce weight loss from a typical 4% to just 0.5%. This results in an immediate 3.5% increase in product yield and profitability.

Yarn quality - correct humidification will maintain yarn strength and elasticity, producing a better quality product with higher margins. Wastage is also reduced through a reduction in shedding.

Static control - Static can cause reduced productivity and product quality due to lint and fly attraction, machine jams and employee discomfort or even accidents. Higher humidity naturally dissipates static charges alleviating these problems.

Weaving efficiency - optimal humidification reduces yarn breakages in weaving, reducing machine downtime as well as loom stop marks and weavers knots in the finished product.

Employee comfort - humidifiers can deliver around 5°C of evaporative cooling to a textile production facility, while suppressing dust, fly and lint. This creates a healthier and more productive atmosphere for employees.

Benefits of working with Condair on your humidification project:

- Multiple decades of worldwide industry experience in textile manufacturing

- Extensive product variety to tailor services to clients' needs

- Innovative agility to create successful solutions for any textile processes

- Full support through expert advice, design, supply, installation, commissioning, maintenance and spares supply

- Production efficiency increase, waste reduction and profit increase

- Increased staff productivity and reduced workplace accidents due to atmospheric optimization

Humidification for the Textile Manufacturing Industry

Low air humidity can dry a fiber causing its internal moisture content to fall. If this moisture content drops below the optimum level during processing, a manufacturer can experience a drop in productivity for a number of reasons.

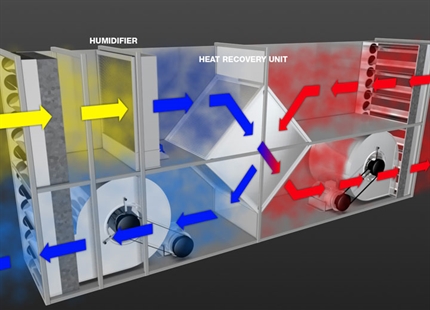

In-duct evaporative cooling strategies

Spray booth humidification

Humidification for Eyes and Skin

Humidification for Instruments

Why Humidify... For Allergies

Why Humidify... For Automotive Manufacturing

Immune Systems

Why Humidify... For Offshore Oil & Gas Platforms

Tobacco production humidification