Humidity and Wood Furniture: 4 Potential Effects

Do you manage a concert hall, oversee production at a hardwood flooring manufacturer or build custom wooden furniture for clients? Regardless, you’ll know the impact indoor relative humidity can have. If levels aren’t tightly controlled, there can be plenty of ill effects no matter what your operating application is. Today, let’s dive into this link between humidity and wood furniture to illustrate the importance of proper humidity control.

1. Adhesion and Lamination Efficiency

When the relative humidity in a space where wood furniture is stored or manufactured is kept between 40 to 60 percent, products maintain a strong adhesion and higher-quality laminate finish. This is useful for furniture with varnished finishes or designs that utilize glue or other adhesives in their construction. In particular, glues often don’t cure evenly in poorly humidified spaces; separation and popping veneers are all too common in such an environment.

2. Dimensional Changes

Wood is known to undergo various changes as air moisture content fluctuates. Some of us associate warping, cupping, checking, splitting, and shrinking with temperature changes on their own without considering humidity, but in actuality, the relationship between humidity and wood furniture is the real culprit. This damage is usually impossible to correct once it occurs, so be sure to implement an industrial humidifier setup that is energy efficient, reliable, and stabilizes relative humidity levels.

3. Quality Control

Yes, proper humidity control leads to improved product quality, but how does this happen when it comes to the manufacturing, storage and use of wooden furniture? Well, at the manufacturing stage, machinery errors can occur due to uncontrolled relative humidity, which can lead to reduced production efficiency as well as lower-quality product output. Furniture stored or used elsewhere, even if manufactured in ideal environmental conditions, can develop dimensional issues and damage as well. All in all, wood is a highly sensitive material; even the hardiest species require sufficient air moisture content management. Don’t leave things to chance!

4. Electrostatic Discharges

Electrostatic shocks can do more than harm employees. In fact, when it comes to wood furniture production, it can introduce dust fires and even static explosions. Alternatively, static electricity may also affect the way paints and finishes adhere to wood materials used in furniture construction.

Whether you want to ensure maximum production efficiency, product quality or a combination of the two, keeping air quality under control with just the right relative humidity for wood furniture is a smart move to make. Help your business save on needless product waste and expenses by optimizing for proper humidity control!

Why Condair

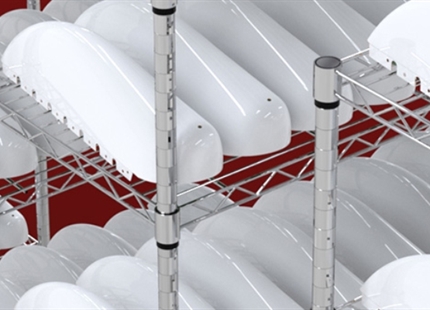

Condair understands the intricate relationship and delicate balance of humidity required for the woodworking industry. Team with our experts to achieve a fully functioning production process while implementing energy-saving techniques and a healthy environment for your employees.

Speak to one of our experts today to learn more about humidification for your facility.

Related Posts

Why Humidify... For Pharmaceutical Manufacturing

Why Humidify for... Life Sciences

Why Humidify... For Composites

Why Humidify... For Clean Rooms

Humidification for Instruments

Humidification for Furniture and Flooring

Why Humidify... For Medical Marijuana

Why Humidify... For Aerospace Manufacturing

Why Humidify... For Textile Manufacturing