Industrial & commercial humidifiers for every application

Condair humidifiers and evaporative cooling systems have been helping improve productivity and health in many commercial, industrial, and residential applications for over 40 years.

Why Humidify... For Hospitals and Care Facilities

Correct humidity is essential to patient health, staff comfort and prevention of electrostatic damage to medical equipment.

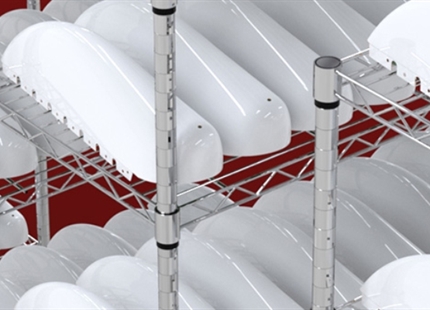

More informationWhy Humidify... For Crop Storage

The optimum humidity can prevent waste and degradation of crops as well as assisting in safe long term storage.

More informationWhy Humidify... For Data Centers

Provides high capacity, low cost evaporative cooling and combats electrostatic discharge that can damage electronics.

More informationIndividuals in the woodworking field such as furniture, cabinetry, and flooring manufacturers often encounter manufacturing issued caused by dry air.

More informationAre you an Engineer working on a project that needs humidification?

Condair offers the widest range of humidification technologies on the market today.

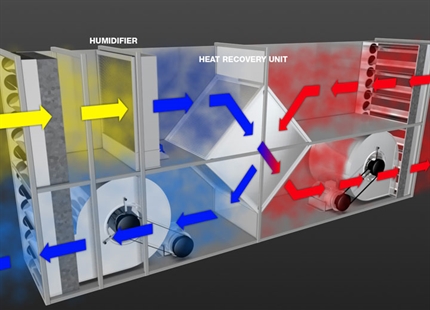

More informationIn-duct evaporative cooling strategies

The three main AHU evaporative cooling strategies explained, covering direct, in-direct and exhaust air cooling.

More informationHome humidification

Improves health and protects furniture, floors and textiles.

More informationWhy Humidify... For Offices

Optimum humidity improves health and productivity of staff as well as reducing absenteeism.

More informationWhy Humidify... For Automotive Manufacturing

Correct humidification within an automotive manufacturing or testing facility will improve production efficiency in several areas across the plant.

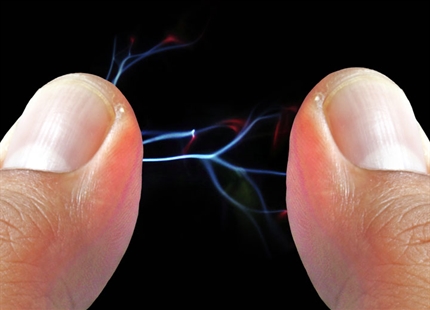

More informationEliminating static with humidification

45-55%RH eliminates the build-up of static electricity in manufacturing environments.

More informationSpa & Wellness

Relax and enjoy the highly innovative steam bath systems from Condair

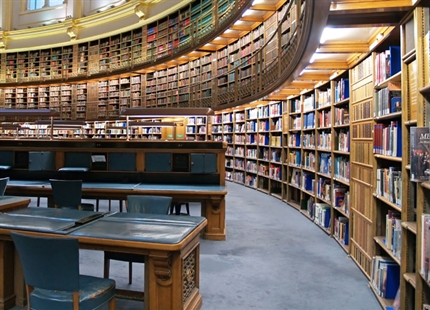

More informationArchives & storage

Proper humidity control is an essential element for long-term preservation.

More informationDehumidifiers for military storage

Using dehumidifiers in military storage facilities is essential to prvent corrosion and damage to expensive military hardware. Dehumidification will...

More informationWhy Humidify... For Printing

Paper is a natural material and very susceptible to changes in relative humidity. If the atmosphere around printing presses and paper storage areas b...

More informationWhy Humidify... For Mushroom Growing

Mushrooms love dark and humid environments. To cultivate mushrooms humidifiers are used to maintain an optimum air humidity of 95%rH.

More informationWhy Humidify... For Pharmaceutical Manufacturing

By ensuring you have proper humidification levels in your pharmaceutical manufacturing facility you will Increases efficiency & yields.

More informationWhy Humidify... For Schools

Proper humidification in schools can reduce absenteeism by 20%.

More informationWhy Humidify... For Egg Incubators

In egg hatcheries, broiler houses and other environments that depend on proper egg incubation, proper humidity plays a crucial role in safeguarding t...

More informationHumidification for Eyes and Skin

Dryness afflicts the eyes, skin and mucous membranes above all. It causes complaints such as stinging eyes, blinking, blurry vision, skin itchiness, ...

More informationPaper & pulp production humidification

Prevents dimensional changes.

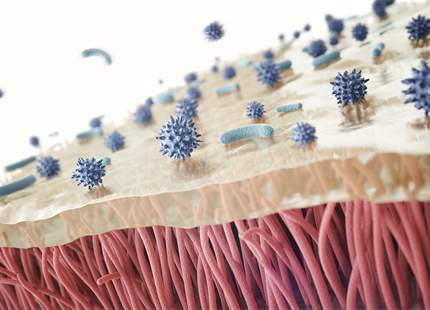

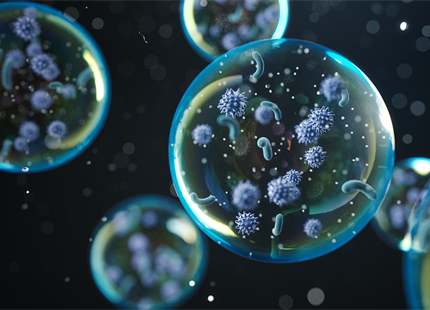

More informationImmune Systems

The immune system is the biological defense system that protects the body against pathogenic microorganisms such as viruses, bacteria and fungi, fine...

More informationWhy Humidify... For Tea Production

Providing proper humidification prevents tea from losing moisture to the air.

More informationWhy Humidify... For Concert Halls

Preserving the dimensions of the sound boards and sliders in organs as well as protecting wooden instruments and auditoriums.

More informationWhy Humidify... For Yoga Studios

We’ve worked with enough hot yoga studios to know how important it is to balance heat and humidity for an optimal yoga environment.

More informationWhy Humidify... For Abattoir

Maintaining a high humidity during the initial chill down of a carcass can reduce weight loss to under 1%.

More informationSpray booth humidification

Prevents evaporation of water-based paints and improves finish.

More informationWhy Humidify... For Germ Reduction

Illnesses are transferred by various pathogenic microorganisms — especially viruses, bacteria and fungus. Bacteria can self-reproduce. Viruses, such ...

More informationWhy Humidify?... 5 Important Points for HR Managers to Consider

Indoor air can be five times more polluted than outside air. Dry stale air can cause physical health problems ranging from itchy eyes, dry throat, he...

More informationWhy Humidify... For Allergies

House dust is the biggest trigger of allergies worldwide. Anyone who is allergic to house dust reacts to either mite constituents or animal allergens...

More informationWhy Humidify... For Bakeries

In bakeries, proper humidification has a profound influence on both product quality and the finished baked good.

More informationTobacco production humidification

Improved product quality and production efficiency.

More informationWhy Humidify... For Retirement & Nursing Homes

In cold seasons when heating systems dry the internal atmosphere the air can often drop below 40% relative humidity (RH). At this level it will draw ...

More informationWhy Humidify... For Hotels & Spas

Hotel rooms, which are humidified between 40 - 60% RH are an additional, important health benefit for your guests.

More informationWhy Humidify... For Greenhouses

Constant and even humidity levels allow plants to thrive.

More informationMedical device manufacturing humidification

Prevents chemical imbalances.

More informationWhy Humidify... For Cheese Curing

When it comes to cheese curing applications, proper humidity control is crucial. Most cheeses need a warm, moist environment with proper air circulat...

More informationWhy Humidify... For Produce

In produce applications such as food storage, proper humidification helps to not only keep food fresh and healthy, but also at a healthy weight and t...

More informationWhy Humidify... For Museums

Dry air absorbs humidity from objects, their weight is reduced and they contract. In the case of humid air, it is the other way round.

More informationPackaging humidification

Reducing static and maintaining the properties of paper, card and adhesives.

More informationWhy Humidify... Cleanrooms & Laboratories Humidification

Laboratories are, in themselves, delicate mini-ecosystems that rely heavily on pinpoint-accurate details, extending to proper humidity.

More informationWhy Humidify... For Supermarkets

Proper humidification ensures that not only does food remain fresher for longer, but also that it is visually appealing. In short, it moves product o...

More informationWhy Humidify... For Veterinary Clinics

Veterinary clinics depend on being clean, breathable environments to encourage not just animal health and welfare, but that of their owners and all o...

More informationWhy Humidify... For Offshore Oil & Gas Platforms

Condair is a specialist in humidification systems for offshore environments.

More informationWhy Humidify... For Textile Manufacturing

Decreases moisture losses to improve product yields, product quality and increase machine efficiency.

More informationWhy Humidify For... Call Centers

With balanced relative humidity (RH) levels, call centers become safer and healthier places to be.

More informationWhy Humidify... For Convention Centers

When hundreds or even thousands of people gather in a space such as a conference center without proper humidity control, relative humidity (RH) level...

More informationWhy Humidify For... Government Buildings

As governments rely more on technology and the people who use it, it is important that the buildings they are in are comfortable, healthy, and suppor...

More informationWhy Humidify... For Medical Marijuana

One need of the growing cannabis plant that is commonly overlooked - is humidity. In all stages of cannabis growth your plants will have a constant n...

More informationWhy Humidify... For Aerospace Manufacturing

The manufacturing process for the aerospace industry relies heavily on a proper humidity level of between 40% - 60%.

More informationWhy Humidify... For Retail Spaces

Proper humidification for retail needs to be consistent, regulated and carefully controlled to ensure the health and comfort of people as well as for...

More informationHumidification for Furniture and Flooring

Individuals that manufacture furniture and flooring often encounter manufacturing issues caused by dry air.

More informationHumidification for Instruments

Musicians place a lot of value on quality of their instruments, even if they play music as a hobby, not professionally. In particular, pianos, violin...

More informationWhy Humidify... For Clean Rooms

The importance of proper humidification for clean rooms not only pertains to comfortable and sanitary working conditions, but also product quality co...

More informationWhy Humidify... For Composites

Composite applications such as creating carbon fiber or similar materials require absolute humidity control to guarantee manufacturing processes that...

More informationWhy Humidify for... Life Sciences

Proper humidity control is essential towards maximizing productivity, efficiency and avoiding waste.

More information