Why Humidify...

For Tea Production

A humid climate favours tea growth in the plantation, and the right relative humidity level is essential to convert the picked leaves into tea during in processing.

During oxidation (also called fermentation in the tea industry), careful control of temperature and humidity is particularly important. This process provides the right conditions for the polyphenols in withered leaves to develop into the theaflavins, thearugibins and other compounds that create the characteristic flavours and colour of black teas, Pouchong and oolongs.

If leaves dry, oxidation slows as water is required for the process. An ambient relative humidity of 95-98%RH at 68-78°F (20-26°C) is required to maintain fermentation, and even a small drop in humidity level will affect the process, reducing yield.

Humidification of other stages, such as in tea bag production to reduce electrostatic problems, also improve productivity.

Tea drinking is growing internationally, and consumers want quality and choice. Together with trends like Fairtrade and direct sourcing in forward contracts, producers are under more pressure than ever to fulfil quotas at the desired quality.

If you can't rely on the climate to provide the right conditions naturally, humidification from Condair is proven to provide a consistent and profitable production environment.

Benefits of Condair humidification in tea production include:

- Guaranteed high humidity (95-98%) for fermentation / oxidation, whatever the outdoor conditions

- Evenly spread moisture throughout traditional floor and tray fermentation rooms, and consistent RH in CTC fermentation - major advantages compared to traditional spinning disk humidifiers

- Reduced leaf discolouration and spotting - reduced waste, higher yield

- Pre-fermentation humidification of rolling and cutting - reduces drying of broken edges

- Faster machine speeds and reduced dust creation in teabag production though electrostatic elimination

- Confidence in your investment - Condair has a strong record of improved quality, productivity and rapid return on investment in the tea industry

Other food-related industries where Condair delivers effective humidity control

Condair Group Announces Appointment of New Chief Executive Officer

Condair Group is pleased to announce the appointment of Martin Plüss as its new Chief Executive Off...

Read moreDesiccant Dryers

Condair DA desiccant dryers are designed to be used especially when an extremely low relative humid...

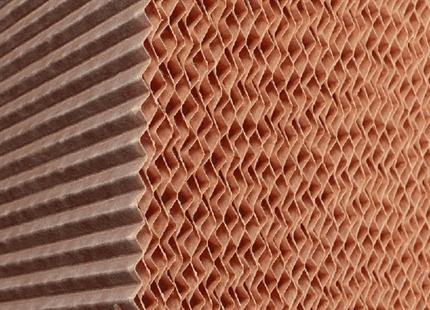

Read moreKuul FirePro glass fiber evaporative cooling media

This superior evaporative media is designed to meet the cooling and humidification needs of the mos...

Read moreCondair Group Expands Presence in the US with New Production Site in Richmond, Virginia.

Marking a strategic move to enhance its proximity to customers and reinforce its position in the Am...

Read moreCondair PH 1000 Pro mobile humidifier

This commercial mobile humidifier is ideal for areas up to 1,000m³ with a maximum output of 2.6l/h....

Read moreWhy Humidify... For Schools

Proper humidification in schools can reduce absenteeism by 20%.

Read moreHealthy Indoors Alliance Comitted to Better Air and Light Quality in Schools

Healthy Indoors, a collaboration between market leaders Condair Group, Camfil, Fagerhult and Swegon...

Read moreLuxury Window and Door Manufacturer uses Condair DR Series Humidifiers to Produce Flawless Products

Precisely and easily managed humidity control opens the door to numerous benefits for luxury manufa...

Read moreCondair Vision, Mission, Values

Get to know Condair's Vision and Mission Statements

Read more