30.10.2019

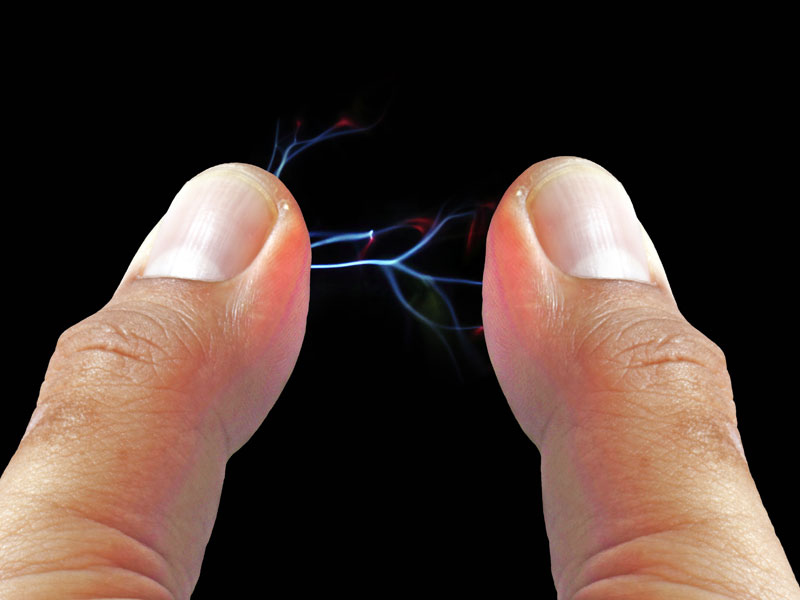

5 Electrostatic Discharge Consequences on Technology

We use technology more and more every day – in fact, more than we may realize. That leaves us open to the risk of electrostatic discharges in low-humidity conditions. In such environments, energy can accumulate on conductive surfaces and arc dangerously to other objects. With the integrity of your servers, hard drives, manufacturing equipment, and other technology in mind, why don’t we take a closer look at the electrostatic discharge consequences of not having regulated, proper humidity control? Doing so could potentially save your company a small fortune in the long run.

Data Corruption

If your hard drive or manufacturing equipment suffers from ESD, data corruption is what you hope the extent of the internal damage is. This means that fragments of data are scrambled and rendered unreadable by system data, but some of it could still be salvaged. This differs from total data loss, which we’ll touch on in a bit.

Static Explosions

If, for example, your application pertains to manufacturing a product that results in airborne vapors or dust, static electricity may create sparks that react violently to such hazards. This is known as a static explosion, and it’s as dangerous a phenomenon as it sounds; worker safety can be put at serious risk and equipment caught in the blast may also be completely destroyed or require costly repairs. The best way to avoid static explosions is to keep electrostatic energy under control with an industrial humidifier, which regulates relative humidity to mitigate the risk.

Data Loss

We’ve covered data corruption already, but that’s a little different from outright loss. For example, if you utilize high-end medical equipment that stores extremely valuable patient data, much of that information may be impossible to find if the system in question has its hard drive wiped. Back in the old days, it used to be that strong magnets could erase some hard drives, but today, the real risk is electrostatic interference. Think of ESD as a naturally occurring EMP of sorts that can do plenty of lasting damage.

Short-Circuiting and Hardware Failures

Nobody wants to deal with hardware failures, especially in manufacturing where specialized motherboards and components could cost a pretty penny – plus downtime representing reduced production – to replace. Short-circuits, battery damage and other forms of failure are all-too-common when ESDs occur. Use the environment to your advantage and implement proper humidity control to curb this risk.

Fires

Some components and materials, such as network cabling and computer batteries, are combustible and can catch fire if ESD occurs. This can obviously represent a major safety risk in addition to lost money and productivity. Ensure such sensitive environments have sufficient air moisture content to minimize the danger.

Want to learn more about proper humidity control for reducing your chances of encountering electrostatic discharge consequences? Contact us at Condair today to learn more about our high-efficiency industrial humidifiers and other solutions. We’re here to help.

Similar Links:

https://www.condair.com/humidifiernews/blog-overview/how-humidity-control-protects-data