05.01.2021

Direct vs. Indirect Evaporative Cooling: What’s the Difference?

At Condair, we pride ourselves on delivering state-of-the-art, high-efficiency evaporative humidifier solutions to suit a variety of applications and subsequent load sizes. These include high-performance evaporative cooling units that can be affixed alongside or installed directly within your ventilation system. However, when it comes to “direct vs. indirect evaporative cooling” it’s hardly a fair matchup and there is no clear “winner;” both systems have their own benefits and ideal use cases. Let’s explore these differences in more detail today.

Understanding the Process

As an example, 690 watts of evaporative cooling is achieved when 2.2 pounds of moisture is introduced to the air stream by way of an evaporative humidifier (otherwise known as an adiabatic humidifier). Using as little as 300 watts of energy, just one of these systems by Condair can deliver a whopping 2,200 pounds of moisture per hour.

Direct Evaporative Cooling

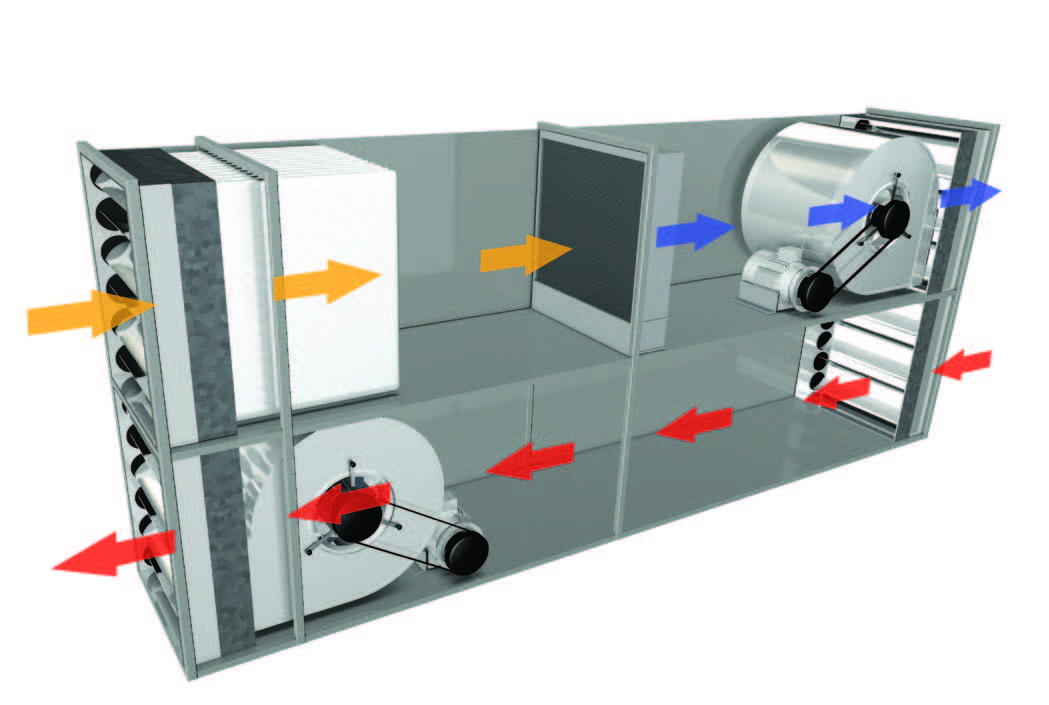

This method utilizes fresh air from outside, which is then brought through ventilation ductwork and met with humidity in a dedicated air handling unit. This airstream with a higher moisture content (relative humidity) achieves an optimal temperature and just the right amount of hydration before being dispersed indoors. That conditioned air is critical as, since a greater amount of existing room air is exhausted, it replaces it and helps to regulate indoor conditions. If the air absorbs more moisture going in due to having lower initial relative humidity, the evaporative cooling effect will be stronger.

Indirect Evaporative Cooling

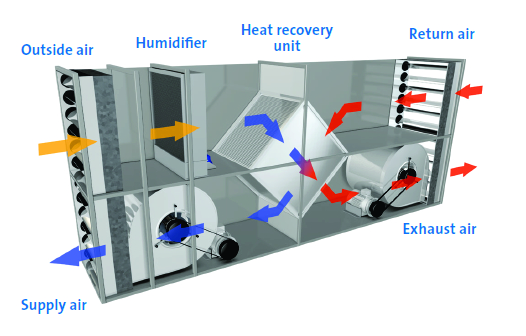

This is a different approach, forgoing the air exchange process of the direct alternative. Instead, outside air is brough through ventilation to lower indoor temperatures without mixing the two air streams. Fresh outside air is run through the evaporative humidifier and AHU's heat recovery (HR) unit and then exhausted without any mixing, while the return air from the room is run through the HR unit. Using this method, if the air temperature after the evaporative humidifier is cooler than the room temperature, it is possible cool the return air before being re-introduced to the room. This method has the advantage of effectively cooling the airstream without over-humidifying the air, because moisture isn’t added to the supply air and the outside air that is being humidified is exhausted. In that sense, indirect evaporative cooling solutions such as those from Condair are useful even in seasonal environments or areas where the outside temperature is higher than indoors.

Use Cases

There are many ways to harness the capabilities of evaporative cooling in direct or indirect formats, and a long list of applications in commercial and industrial environments reap the benefits as a result. For instance, Condair’s solutions are popular in data centers where indoor temperatures and electrostatic discharge potentialities need to be tightly managed, in food preparation and storage environments where quality control depends on precise indoor climate control, and factories that need to keep employees safe, comfortable and efficient.

To recap on the “direct vs. indirect evaporative cooling” argument, both are clear winners in respect to their ideal use cases. Depending on your required load capacity, operational needs, what risks you need to mitigate and the layout of your facility, either or both variations of the technology may be a great choice. Contact us at Condair today if you’d like to learn more or narrow your options down to the right one.