Steam Humidification: How to reliably prevent limescale in pipes

Limescale deposits are an everyday issue, but one that has complex negative implications in many industries. While it is only a nuisance in accessible components, lime poses a challenge in other places such as pipelines, and in devices whose function and service life are impacted by lime deposits. Room humidification often comprises all the factors for problematic limescale formation: lime-containing water, elevated temperatures, and small cross-sections in such elements as nozzles and pipes. It is therefore necessary to find solutions for limescale build-up and ensure optimum indoor humidity.

Dry indoor air must be avoided for a number of reasons in both private and public spaces. Air quality is not only vital to our well-being and performance, but a sufficient relative humidity (RH) is also crucial to many industries for preventing damage to hygroscopic materials, disruptions in automated manufacturing processes and undesirable material changes.

Prevent limescale in your building by using the right humidification system

Contact Us

Steam humidification technologies

If the steam is to be generated directly at the point of use, electrically operated steam humidifiers are a good option.

Humidifiers can generate steam via two different isothermal processes. In one process, fresh water is heated by a grid of metal electrodes in the water tank, with the current flowing directly over the water medium causing evaporation.

The other process is based on the resistance heating principle. With this method, immersed heating elements boil water, generating steam in a steam cylinder with several resistive heating elements. At the latest, when comparing it with the immersion heater, images of calcified heating coils of the household appliances of bygone days are likely to come to mind immediately.

Depending on the requirements for room air quality and the structural conditions, there are two ways of humidifying the air: either indirectly, via the room air conditioning system (AHU), or directly, via a device installed in the room. Direct room humidifiers are frequently used regardless of existing air conditioning systems. The appropriate accessories can enable a connection between an AHU system and a direct room humidifier. In commercial and industrial humidification, steam humidifiers have performed very well.

Lime – and how it gets into drinking water

To understand the impacts of lime, we must first understand how it enters the water cycle, beginning with precipitation. Rain, snow and hail either land directly in bodies of water or seep into the ground. Below the soil, the water then enters deep rock layers that contain calcium carbonate, a primary mineral in lime. Further along the cycle, the water reaches the bedrock at a depth of hundreds to several thousand meters, varying by region. From there, this groundwater eventually flows into lakes and oceans, where is can be evaporated when exposed to the heat of the atmosphere. On its long journey, the water absorbs minerals and trace elements from the earth's crust and varying amounts of lime.

For indoor humidification, the issue of lime is a major challenge. Though the calcium carbonite composition of drinking water is not always harmful to human health, it is a problem for the function and service life of technical equipment and is therefore a key consideration for deciding on a humidification system for your space. Remedying lime build-up can require maintenance, cleaning, and water treatment at additional costs.

Avoiding limescale deposits from the outset

Some humidification technologies are capable of breaking lime build-up within their machinery into small particles and washing them away. However, this can transfer the blockage to the building's plumping system, causing damage there. If left unmaintained, pipes may even have to be replaced prematurely. In addition, calcium carbonate deposits provide the ideal breeding ground for microorganisms that are harmful to health. Over time, these form a biofilm on the inner walls of the pipes, resulting in a continuous release of germs.

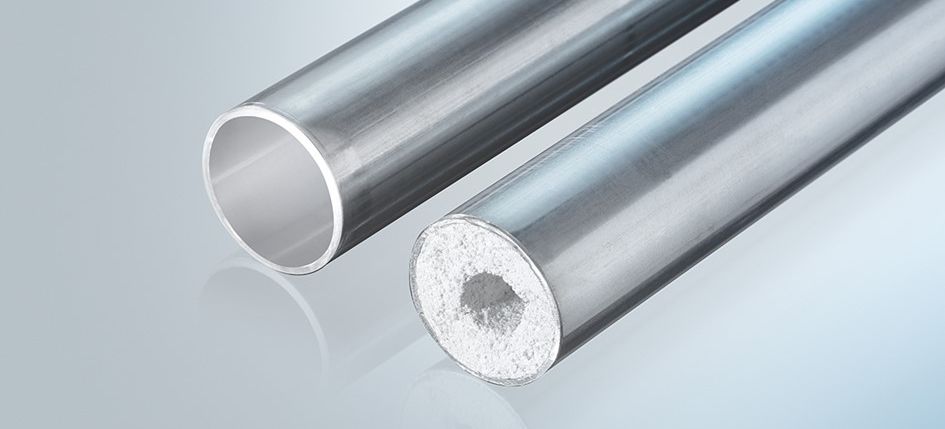

Image 1: Lime deposit in the building

Image 1: Lime deposit in the building

Image 2: Patented lime management with the Condair RS

Conclusion: Prevention instead of expensive replacement

The best method for mitigating the challenges of lime is preventing limescale deposits from forming in pipelines from the beginning. Specialized water treatment for decalcifying drinking water in advance is expensive and requires frequent maintenance, depending on the size of the property. Alternatively, the patented lime management of the Condair RS offers an effective, hygienic, and easy-to-use solution for limescale deposits and doesn't require prior water decalcification treatment for room humidification. Limescale deposits are prevented here by automatically directing the minerals found in the steam cylinder into a special collection container called a scale collector tank. This scale collector is accessible and easy to empty. Maintenance for this system is therefore minimal and is only required on the RS device itself.

Since resistance heaters operate independently of the conductivity of the humidifying water, both treated water and drinking water containing lime can be used. Even with hard water of more than 2.5 mmol calcium carbonate/l and more than 14° dH, such humidifier systems work reliably and ensure optimum room humidity with manageable maintenance requirements that prevent deposits in the piping system.

Related Posts

Commercial Humidifiers and Industrial Humidifiers: Why are they so Important?

No matter what kind of business you operate, it thrives on an environment fit for human occupation ...

Read moreWhy Upgrade to a Modern Humidifier?

Let’s say that your business has been using an older humidifier for years at this point. It’s likel...

Read moreCondair's Healthy Building Solutions Checklist: How Does Yours Stack Up

At Condair, we love helping our clients optimize their building operations. Health, like safety and...

Read more