01.14.2020

Why Controlling Indoor Humidity in Winter Conditions Matters

Old man winter has settled right in for a long visit, meaning cold temperatures, inclement weather and a need to spend more time indoors is upon us. With that said, it’s surprising how many businesses don’t prioritize proper humidity control in their operating environments. Whether you’re a candy maker or aerospace manufacturer, keeping conditions just right with adequate relative humidity (RH) can create the ideal atmosphere for your employees, visiting clients and other occupants.

Today, let’s explore in detail why controlling indoor humidity in winter conditions matters so much!

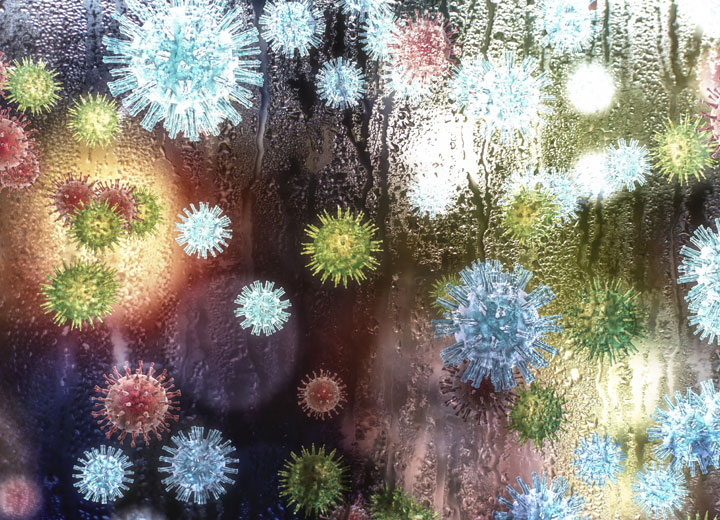

Flu Prevention

Airborne infection control is never more important than during the dreaded flu season. If you operate a hospital, clean room, nursing home or other healthcare-associated application, be aware of how your ventilation system and indoor relative humidity control functions. Implementing a proactive humidification strategy can protect against spikes in absenteeism and the spread of person-to-person contagions.

But how does the flu spread in the first place? To simplify, clumps of bacteria housed in air moisture content are dispersed into the air freely when the indoor relative humidity is too low (less than 40 percent). These are known as aerosols, and they can be home to various bacterial strains, allergens and other nasty infectious microbes. With proper humidity control achieved by keeping RH levels between 40 and 60 percent, the aerosols will fall and settle more quickly. In winter conditions, particularly during flu season, the presence of bacteria indoors can increase, much like how sweltering conditions in the summer can do the same.

Cost Control

High RH levels in the wintertime can represent higher operating costs for your business. By keeping temperatures and air moisture content under regulated, consistent control, your operations won’t have to endure unforeseen fluctuations in energy billing. In fact, with solutions such as Condair’s industrial humidifiers, many applications benefit from a further reduced carbon footprint thanks to their energy efficiency and high dependability. From single-person households to sprawling industrial complexes and corporate office towers, ensuring proper humidity control means having an ideal option that accommodates for every application and required minimum load capacity.

Comfort and Wellness

Ever spend the Christmas holidays at a loved one’s house where the air is drier than the turkey on the dinner table and peppered with airborne dust? These symptoms of low relative humidity can be found in industrial and commercial environments as well, and at a much larger scale.

When we crank the heat, shut the windows and prepare to hunker down for months of cold weather, the amount of hydration introduced to indoor air drastically declines. This introduces a host of problems including respiratory issues, itching and discomfort, dry eyes and lips, trouble focusing and staying alert, increased dust particle presence, and a higher risk of electrostatic discharges.

Equipment Performance and Quality Control

As for your equipment, electronics and the like can easily be damaged in low-humidity conditions where electrostatic discharges can damage computer internals and exhaust vents for heat-generating equipment can become clogged with dust, leading to increased failure rates. In a way, proper humidity control doesn’t just lower energy consumption but also helps business owners cut down on IT-related expenses, achieved through minimal repairs and easier-to-maintain workstations.

Having equipment that works properly and is free of risks from the environment also leads to improved focus on output, boosting it with more machinery being usable at any given time. Plus, quality control will benefit from the improved performance of your equipment and wasted material counts will drop. Another aspect of quality control relative to humidity control involves specific applications that require consistent relative humidity levels and air cleanliness. Coatings will be smoother and less prone to production errors, paint spraying booths can operate without the dangers of an electrostatic charge triggering an ignition, and healthcare environments can reduce the spread of illness and maintain indoor spaces conducive to patient recovery with less risk of infection.

Controlling indoor humidity in winter, with an industrial humidifier is essential to a happy, healthy business. Keep employees safe, production at its peak and customers satisfied all while lowering general costs with the help of today’s high-efficiency solutions, and you’ll never want to go back. Contact us at Condair today to learn more about our available industrial humidifiers, commercial humidifiers, evaporative coolers and other solutions.

Similar Links: